Field of Application: Acoustic Blade Vibration Excitation

- Contactless blade vibration excitation in turbomachinery test rigs

- Experimentally aeroelastic investigations

Description: Acoustic Blade Vibration Excitation

A key problem is the experimental validation of the models. This requires highly accurate vibration experiments on rotating machines.

For a realistic investigation of blade vibrations, it is therefore important to be able to excite the rotating blades without contact so that the vibration characteristics of the blade are not changed by the excitation mechanism itself. A system for acoustic blade vibration excitation was therefore developed at TFD as part of a research project. In addition to non-contact excitation, acoustic excitation offers a high degree of flexibility in terms of excitation frequency and excitation intensity. Furthermore, the excitation of different vibration modes is possible.

To implement a completely contactless test environment, the acoustic excitation is combined with an optical tip timing system for blade vibration measurement. The result is a powerful test environment that is used at TFD for the realistic investigation of aeroelastic effects in turbomachinery.

Field of Application: Blade Vibration Excitation with Piezo Actuators

- Experimental aeroelastic investigations

- Blade Vibration Excitation in turbomachinery test rigs

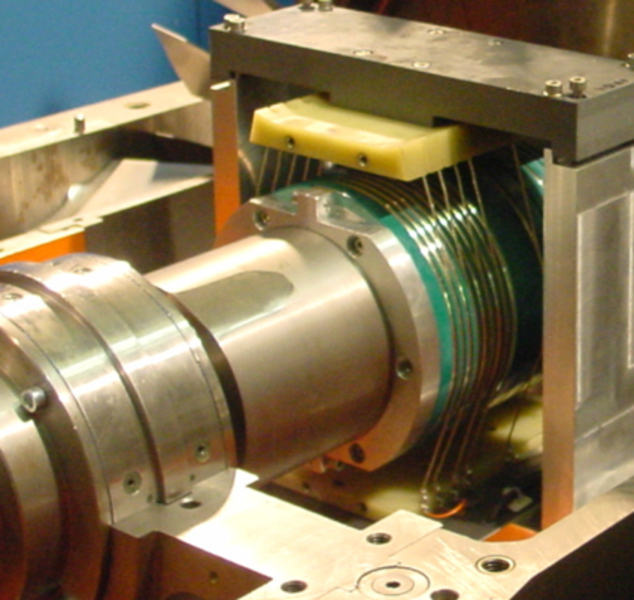

Description: Blade Vibration Excitation with Piezo Actuators

The transfer of the excitation and the measurement signal from the rotating to the fixed system is done via slip rings. The current instrumentation allows excitation of the first bending mode during compressor operation. Both the excitation frequency and the excitation intensity can be varied via the voltage supply to the piezo actuators. The excitation system is fully functional and is used for aeroelastic investigations.