Skills

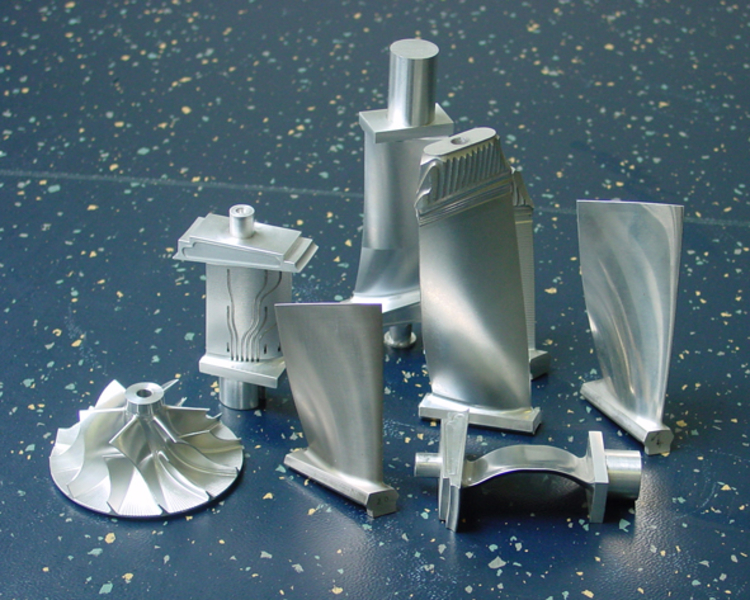

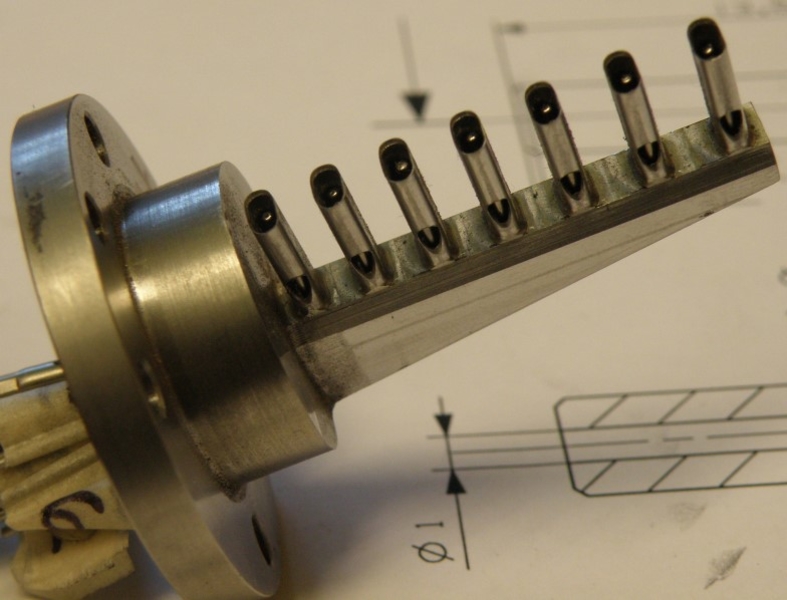

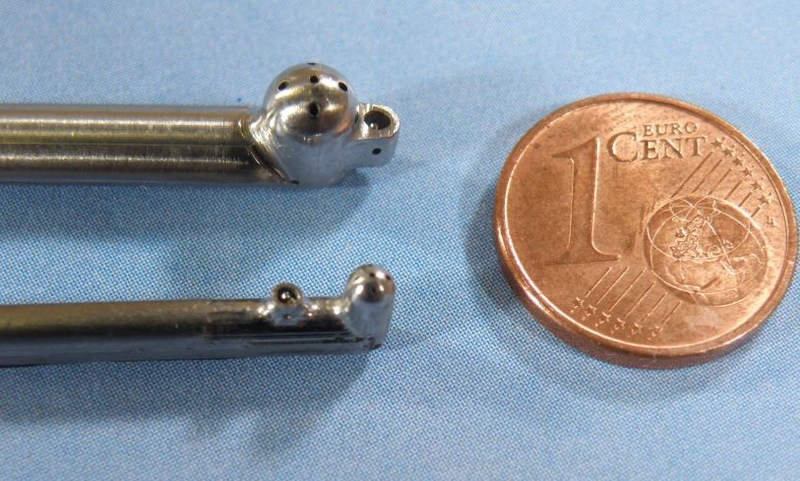

This equipment allows the technical staff to manufacture very complex components. As a supporting link in the chain of a manufacturing process, the workshop fits seamlessly between the areas of design and commissioning on the test rigs as a production environment for the required components. A special expertise of the TFD staff is the blade manufacturing of compressor and turbine blades, both for axial and, in the future, for radial machines. Another competence is the manufacturing of different flow probes. A selection of some manufactured blade profiles and flow probes is shown on the right. Due to the broadly based competences of the employees (master craftsmen, technicians, precision mechanics, electronic engineers), a wide range of tasks can be carried out.

Another important area at Leibniz University is the training of specialists. In the technical area of the TFD, approx. 4-6 trainees regularly undergo technical training at the same time (precision mechanics with a focus on precision engineering). The range of tasks and work is very diverse and varied due to the research activities of the institute.

Contact

30823 Garbsen