Description

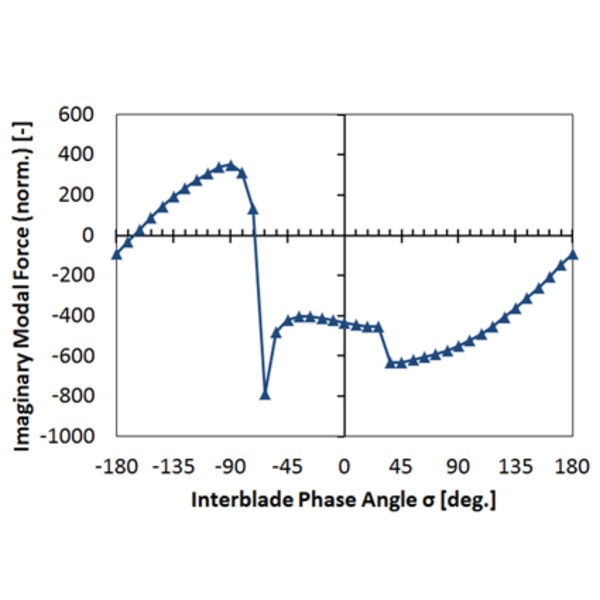

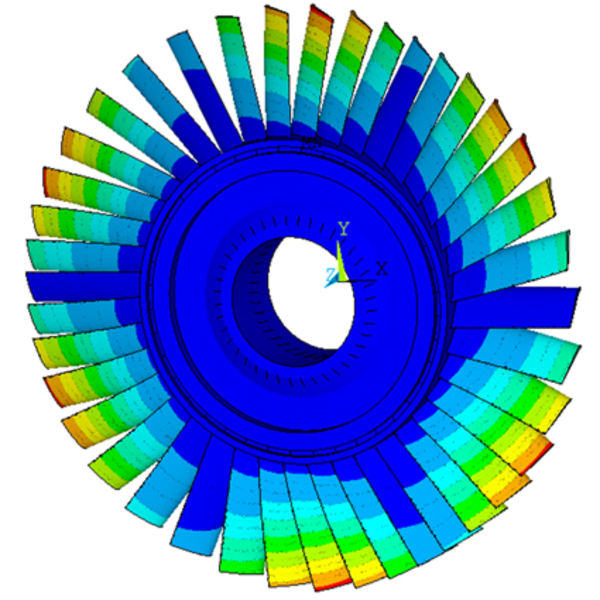

In flow simulations which do not involve structural interactions, the body is assumed to be rigid. This assumption is a simplification of reality because the forces acting on the body can elastically deform it. The change in body shape influences the flow field around the body and the forces acting upon it. These interactions can lead under certain circumstances to aeroelastic instabilities which can result in damage to parts. Aeroelastic phenomena must therefore be considered during the design of turbomachinery and wind turbines.

Turbomachinery flows are inherently unsteady and therefore induce highly variable loads on the blade surfaces. These changing loads can lead to fatigue failure in parts. Aside from forced vibrations (forced response) due to wakes or potential effects, resonant vibrations (flutter) can also occur.

The aeroelastic behavior of wind turbines is not only influenced by the interaction between the aerodynamic forces and the elastically deformed structure. Additionally, pitch control and the electric generator can significantly affect aeroelastic behavior. During the design process it is therefore very important to consider the aeroelastic effects resulting from component coupling in the whole construction. Such effects include the coupling between the drive train torsion and the edgewise bending of the rotor blades, or the coupling of the tower bending and the flapwise bending of the rotor blades. Stall-induced vibrations, classical flutter, and instabilities of the edgewise blade and tower bending modes are aeroelastic instabilities that can be experienced by wind turbines.

The TFD offers various facilities for the simulation of these phenomena in the fields of turbomachinery and wind turbines. These include time-domain methods together with linear and nonlinear frequency-domain methods.

Field of Application

- Turbomachinery

- Wind turbines

Software Packages

-

ANSYS CFX

Commercial flowsolver package for steady-state and unsteady flows (finite-volume method)

-

ANSYS Classic

Commercial solver for structural mechanics (finite-element method)

-

linearTRACE (Turbomachinery Research Aerodynamic Computational Environment, DLR)

Time-linearized frequency domain solver for aeroelastic simulation in turbomachinery (finite-volume method)

-

SIMPACK

Commercial solver for multi-body systems, the solver can be coupled with the aerodynamic solver AeroDyn for the simulation of wind turbines. AeroDyn is based on the blade-element momentum (BEM) theory and was developed at the US National Renewable Energy Laboratory (NREL).

-

FAST

Integrated solver for aeroelastic simulations of wind turbines, which was developed at the US National Renewable Energy Laboratory (NREL). It couples the BEM-solver AeroDyn (see above) with a modal and multi-body system modeling to simulate the structural dynamics of a wind turbine. FAST can work in the time domain or can linearize a non-linear aeroelastic model of a wind turbine.