Field of Application

- Optical measurement of the influence of defects in the flame on the exhaust gas temperature profile

- Validation of numerical simulation models

Description

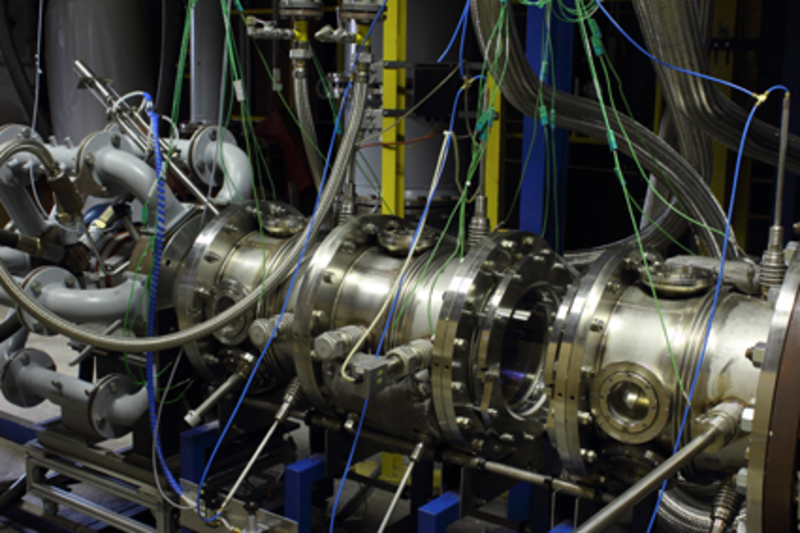

The burner consists of a pilot flame (diffusion flame) and main flame (premixed flame). A Roots-blower supplies the test rig with combustion air, set into rotation by a variable swirl generator and mixed with the gas of the main flame before the ignition in the pilot flame.

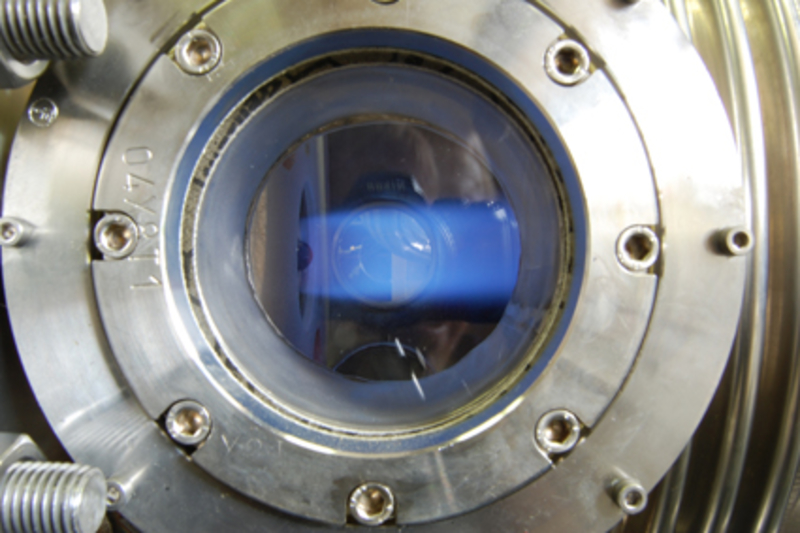

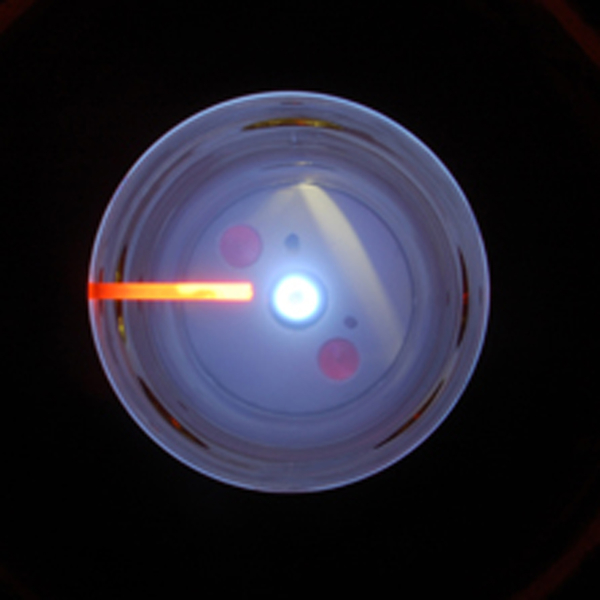

The air-cooled flame tube of the test rig consists of 4 segments. Each segment has a number of differently sized access points. In the first segment, optical studies with the particle image velocimetry (PIV ) can be performed directly on the flame through five optical access points of diameter 90 mm (see Figure 3). A special feature of the test bed is a segment with an integrated quartz-glass-tube (see Figure 1). This allows tomographic measurements using the background oriented schlieren method (BOS). The maximum wall-temperature of the segments, which are made of Alloy 800, is 800 °C. Al2O3 moldings can be used to increase the wall-temperatures up to 1 250 °C.

Measurement Techniques

- PIV

- BOS

Specifications

| Maximum thermal power | 450 kW |

| Air mass flow | 0,06 - 0,25 kg/s |

| Maximum pressure increase | 1 bar (ü) |

| Air ratio | 1,5 - 2,5 |

| Variable swirl | 0° - 45° |