Field of Application

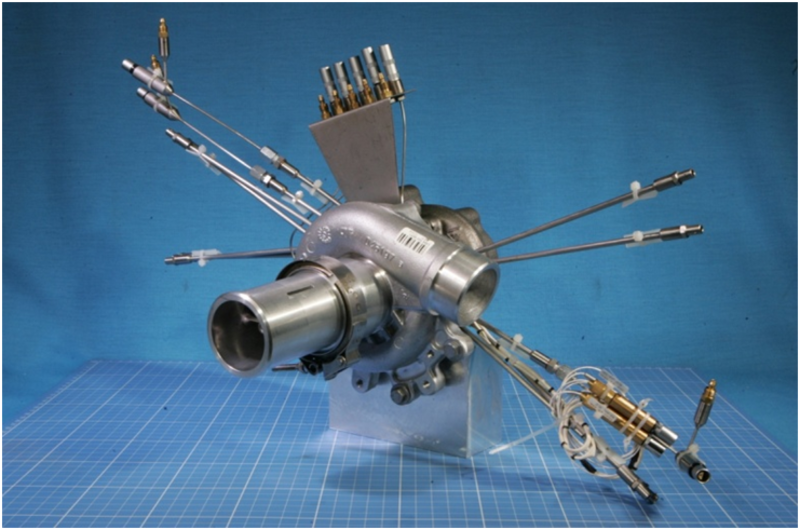

Steady and transient performance measurements of:

- single and dual-flow turbochargers

- fuel cells charging

- electrically driven compressor

- hot gas component tests

Description

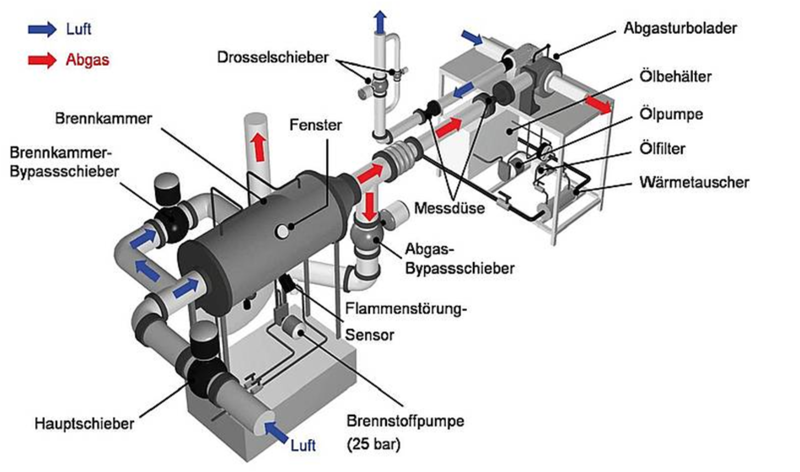

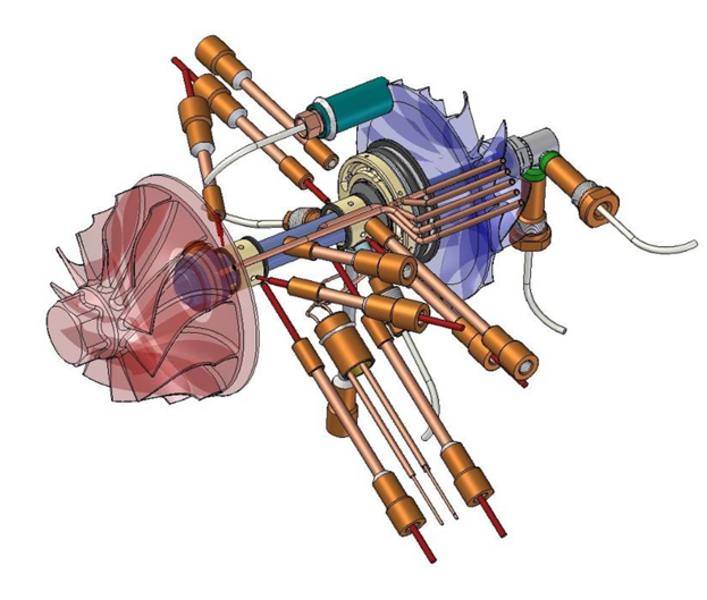

For the successful implementation of future research projects, in this new test bench the most up-to-date and highly accurate measuring and control techniques has been combined with the high degree of flexibility of the possible applications. The versatility of the possible fields of application of the test rig requires a modular test stand with a very precisely tuned infrastructure. Therefore, the test bench is equipped with two hot gas generator systems (HGG), a compressor back pressure unit (CBPU) to adjustment of the compressor boost pressure, a conditioning of the lubrication oil (OCU) to control the pressure and temperature conditions in the bearing and a conditioning of the cooling water (WCU) to maintain a uniform input temperature for water-cooled bearing housings.

To vary the operation setting of the turbine over a wide range independently of the compressor, a compressor closed loop Unit (CCLU) is used. The high reproducibility of the operating conditions is the perfect basis for producing reliable measurements and consequently providing thorough and reliable information on the setup or system investigated.

The Test Facility was partly financed by the European Community under an EFRE grant. The Test Facility is located at the Energy Research Centre of Lower Saxony (EFZN) at Goslar.

Measurement Techniques

- Steady state and unsteady pressure probes

- Temperature measurement (Type K & Pt100)

- CTA/CCA probes for velocity vector and turbulence measurement

- L2F, PIV for flow field measurement

- Tip-timing system for blade vibration measurement

- Blow-by measurement system Acceleration sensors for monitoring vibrations

- Rotordynamic measurements (Eddy-Current Probes)

- Control and analysis of power electronics

Specifications

Low-Flow Hot Gas Generator | High-Flow Hot Gas Generator | |

|---|---|---|

| Turbine inlet temperature | 40 - 1050 °C | 40 - 1050 °C |

| Turbine inlet pressure | up to 6 bar (abs.) | up to 6 bar (abs.) |

| Maximum turbine mass flow rate | up to 0.3 kg/s | up to 0,8 kg/s |

Contact

Management DEW

30823 Garbsen

Management DEW