Field of Application

Investigation of linear cascades

Description

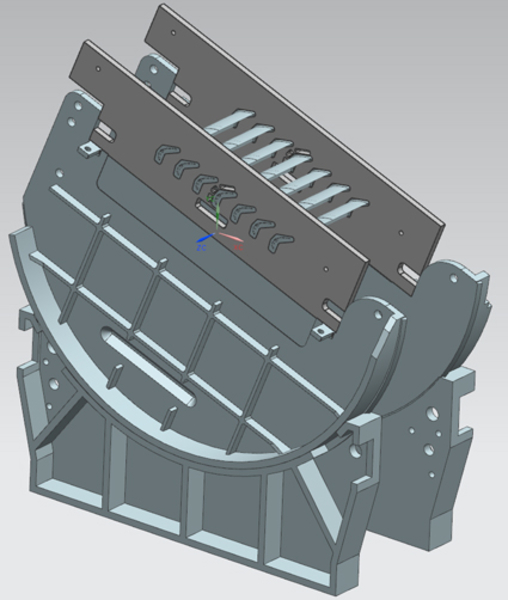

The linear cascade wind tunnel has a channel width of 240 mm and a channel length that can be set between 120 mm and 776 mm. The channel length is dependent on the angle of attack, the pitch, and the number of blades inside the cascade box which is being used. The swiveling head supports a continuous variation of the angle of attack between 90° and 151°.

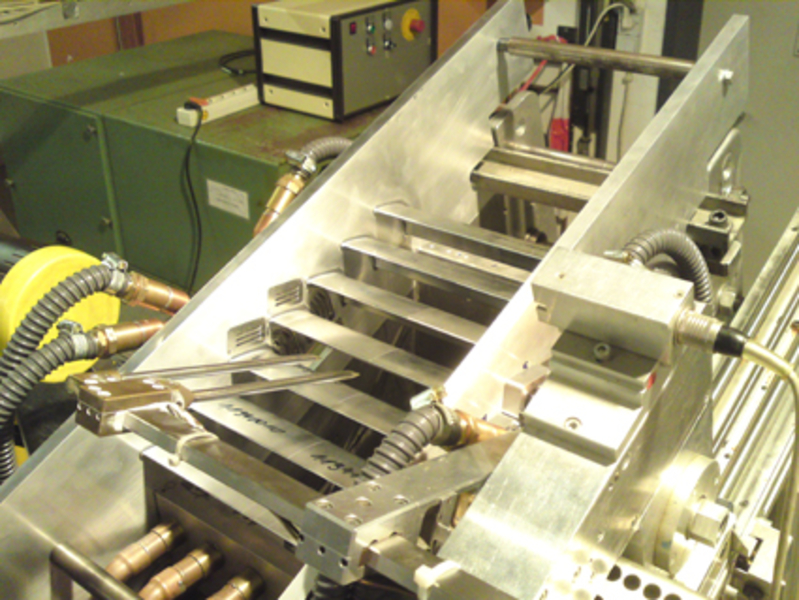

Each position in the cascade box can accept either a single full-span profile or two half-span profiles. The use of two half-span profiles offers the opportunity to perform highly accurate relative pressure measurements comparing different blade modifications with a reference blade; these modifications could be surface roughness or geometric variations.

A probe head containing two individual wedge-type probes moves pitch-wise. These support the simultaneous measurement of the two profile parts. Environmental conditions affect the measurement of both the reference blade and the modified blade.

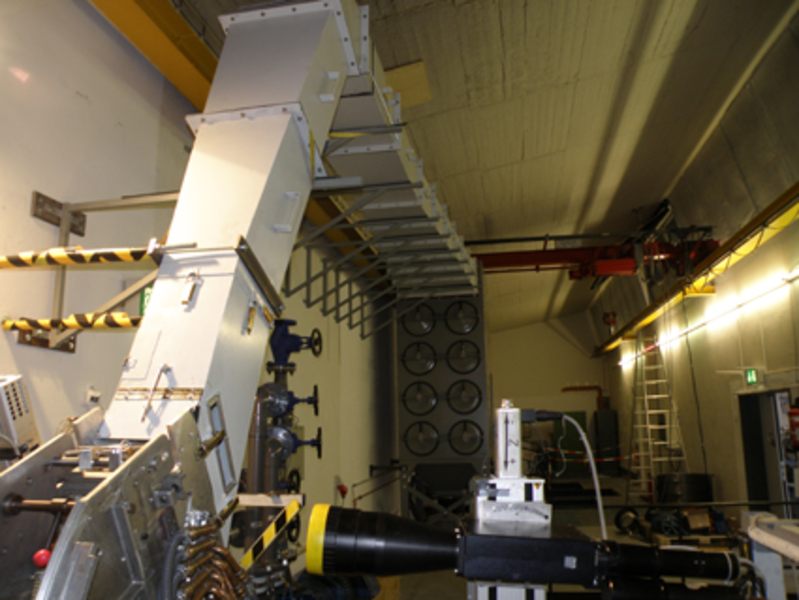

The air supply of the linear cascade wind tunnel is provided by three screw-type compressors with a maximum mass flow rate of 11 kg/s. The inflow velocity can be adjusted infinitely so that the Mach number can range between Ma = 0.01 and Ma = 0.8, depending on the airfoil investigated. This leads to a Reynolds number range from Re = 100 000 to Re = 1 200 000. In order to ensure a two-dimensional velocity distribution over a wide span range, a Roots blower provides boundary layer suction at the endwalls, where static pressure tabs are used to observe the boundary layer growth.

The linear cascade wind tunnel can be fitted with a type SFC-16-4H55 cartridge filter arrangement, which allows conclusions to be drawn regarding the surface contamination and erosion of turbine or compressor blades. Well carefully considered quantities of particles can be injected into the main flow by a lance. Particles can be measure by a L2F system that has been adapted for this purpose. The contaminated air of the outflow is filtered by the cartridge filter arrangement. A great advantage of this installation is that wedge-type probes and the cartridge filter arrangement can be used simultaneously.

Measurement Techniques

- Steady and unsteady pressure measurements

- Constant Temperature Anemometry (CTA)

- Laser Two Focus (L2F)

- Linear Doppler Anemometry (LDA)

- Particle Image Velocimetry (PIV)

- Background Oriented Schlieren (BOS)

Specifications

| Channel width | 240 mm |

| Channel length | 120 - 776 mm |

| Blade chord length | 50 - 120 mm |

| Angle of attack | continuously 90° - 151° |

| Mass flow rate | up to 11 kg/s |

| Mach number | 0,01 - 0,8 |

| Reynolds number (according to blade chord length) | 100.000 - 1.200.000 |

Contact

30823 Garbsen